HAZEMAG Secondary Impactor APS, APSM

2022年7月6日 Series Secondary . Impact Crusher is ideally suited for crushing medium-hard rock down to a well graded, highly cubical product size of 0 – 3 inch. Due to its

Онлайн консультация

IMPACT CRUSHERS - HAZEMAG

IMPACT CRUSHERS. PRIMARY IMPACT CRUSHER HPI; Primary Impact Crusher HPI-H; Secondary Impact Crusher HSI; Tertiary Impact Crusher HTI; Compound Impact

Онлайн консультация

What Is A Secondary Impact Crusher - MEKA

Blog WHAT IS A SECONDARY IMPACT CRUSHER? WHAT IS A SECONDARY IMPACT CRUSHER? Secondary impactors are widely accepted as the machine of choice as secondary reduction units for

Онлайн консультация

McLanahan Impact Crushers - Secondary

Impact Crushers - Secondary. The NGS Impact Crusher is extremely versatile. The most common application involves taking primary-run limestone from either a Jaw Crusher or

Онлайн консультация

Nordberg® NP Series™ impact crushers - Metso

Nordberg® NP Series™ horizontal shaft impact (HSI) crushers are known for high reduction ratios when processing all type materials. They deliver unbeatable performance in

Онлайн консультация

Secondary Impact Crushers

2022年6月26日 Secondary Impact Crushers are designed for crushing the soft and the hard materials. They are mainly used to crush soft medium soft stones like limestone

Онлайн консультация

Portable Secondary Impact Crushers - MEKA

DESCRIPTIONS ABOUT Portable Secondary Impact Crushers DOWNLOADS APPLICATIONS Equipped with a horizontal shaft impact crusher and a feed hopper with belt feeder, it is designed especially for

Онлайн консультация

Secondary Impact Crusher Willpactor II®

The Williams Willpactor II is a rugged, secondary impact crusher designed to increase efficiency while providing reliable product control. This heavy duty secondary crusher is designed specifically to increase profits by

Онлайн консультация

APS Secondary Impactor Hazemag North America

64 x 118. (1600 x 3000) 113,500. (51,590) The APS Series Secondary Impact Crusher is ideally suited for crushing medium-hard rock down to a well graded, highly cubical product size of 0 – 3 inch. This machine is widely accepted as the machine of choice for the North American Aggregate Industry.

Онлайн консультация

Nordberg® NP Series™ impact crushers - Metso

High performance. Nordberg® NP Series™ HSI crushers consist of heavy rotor, wear resistant materials, and an optimal crushing chamber design. This combination has proven revolutionary in improving capacity and product quality, as well as in reducing operating and wear costs. Nordberg® NP™ crushers have a unique blow bar attachment system.

Онлайн консультация

CRUSHERS - mekaglobal

2022年6月27日 Crusher Speed rpm 330 330 293 228 210 330 330 Capacity mtph 20-110 30-120 50-250 100-300 275-600 20-110 110-220 stph 22-120 33-132 55-275 110-330 302-660 22-120 120-242 ... MEKA Secondary impact crushers feature a unique combination of heavy rotor design, wear material and crushing chamber design. These features result in

Онлайн консультация

HAZEMAG Secondary Impactor APS, APSM

2022年7月6日 Series Secondary . Impact Crusher is ideally suited for crushing medium-hard rock down to a well graded, highly cubical product size of 0 – 3 inch. Due to its operational flexibility, economical operation and excellent product size control, this machine is widely accepted as the machine of choice for the North American Aggregate Industry.

Онлайн консультация

What is a Primary Crusher? - machinerypartner

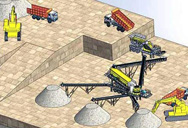

A primary crusher breaks up large pieces of rock or concrete from the blasting or excavation process and turns them into smaller, more manageable chunks. This is the first step in the crushing process. The smaller pieces can then either be pre-screened or fed directly into a secondary impact or cone crusher.

Онлайн консультация

A Comprehensive Guide to Secondary Crusher Types

2023年2月28日 Learn about the different types of secondary crushers, including impact crushers, cone crushers, roll crushers, and jaw crushers, and their functions, advantages, disadvantages, applications, and factors to consider when selecting them. Discover case studies and examples of successful applications, as well as future developments in

Онлайн консультация

Portable Secondary Impact Crushers - MEKA Concrete Plants

Equipped with a horizontal shaft impact crusher and a feed hopper with belt feeder, it is designed especially for processing soft and medium-hard materials, such as limestone and recycled materials. They can be used in multistage crushing process or as a stand-alone unit crushing pre-crushed material. WHY MEKA PORTABLE SECONDARY IMPACT

Онлайн консультация

Primary and Secondary Crushing: Understanding the Basics

2023年2月28日 The secondary crusher is the equipment that reduces the size of the materials further, after they have been reduced by the primary crusher. The secondary crusher has a size reduction ratio ranging from 3:1 to 5:1. The secondary crusher can be a cone crusher, impact crusher, or gyratory crusher, depending on the hardness,

Онлайн консультация

Secondary Impact Crusher Willpactor II® Williams Crusher

Call (314) 621-3348, email us at info@williamscrusher or locate an agent near you. The Williams Willpactor II is a rugged, secondary impact crusher that can even be used as a tertiary crusher. It provides efficiency, economy and the durability through selective reinforcement of critical components.

Онлайн консультация

APK Secondary Impactor Hazemag North America

APK Secondary Impactor. The APK Series Secondary Impact Crusher is ideally suited to crush medium-hard materials down to a highly cubical, well graded product size of 0 – 3 inch. This machine is normally offered within an aggregate plant / system where tertiary crushing is also present. Due to its high reduction ratio, the need for multiple ...

Онлайн консультация

Primary Center Sizer HCS - HAZEMAG

For industrial beneficiation of primary and secondary raw materials, selection of the most appropriate crushing method plays a key role in the production of specific grain sizes, shapes and surfaces, or to break down multi-component materials. The selected crusher must conform to today’s stringent requirements for processing rocks, ores and ...

Онлайн консультация

Industrial Solutions Impact crushers - ThyssenKrupp

2022年11月21日 Stationary single-shaft impact crusher fed by two apron feeders at Cementos Progreso S.A., Guatemala Type PB 200/250 CR Throughput rate 1,100 t/h Mobile impact crusher with hydraulic walking mechanism at Martin Marietta, Texas, USA Type PB 250/300 CR Throughput rate 4,500/2,700 t/h Mobile wheel-mounted impact crusher

Онлайн консультация

Concrete aggregates properties crushed by jaw and impact secondary ...

2019年1月1日 Particle size distribution curves of recycled aggregates from building demolition concrete crushed by jaw and impact crushers. The jaw crusher produced 60% of coarse aggregates in weight, whereas the impact crusher produced 49% coarse aggregates. The proportion of particles finer than 0.15 mm is around 7–8% weight for both crushing

Онлайн консультация

Types of Crushers: What You Need to Know - Machinery

The primitive impact crusher was made up of a wooden box, cylindrical wooden drum, with iron hammers fastened to it. While both of these patents were granted, neither creator ever marketed their inventions. ... The average input size for a secondary crusher ranges from 13" to 4" during this stage. Secondary crushing is especially important for ...

Онлайн консультация

Crusher - an overview ScienceDirect Topics

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Crushers. Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer

Онлайн консультация

Primary vs. Secondary Crushers: Understanding the

2023年2月28日 The crushing process involves the use of crushers to break down rocks and stones into smaller sizes. The primary crusher is used to reduce the size of the initial rocks, while the secondary crusher further breaks down the smaller pieces into finer materials. Purpose and Benefits of Using Primary and Secondary Crushers.

Онлайн консультация

Selecting the Right Crushing Equipment Agg-Net

2015年10月28日 The output gradation of the primary HSI crusher is generally coarser than the primary breaker due to the lack of expansion above the rotor, which also affects the capacity. Primary HSI crushers are considerably wider than primary breakers at comparable capacity ratings. Secondary horizontal-shaft impact (HSI) crushers

Онлайн консультация

Secondary impact crusher for non-metallic ores - LinkedIn

2023年9月20日 A secondary impact crusher is a type of crushing machine used in the mining and aggregate industries to reduce the size of non-metallic ores. It plays a crucial role in the ore processing and ...

Онлайн консультация

Impact Crushers - Parker Plant

2023年11月24日 The Kubitizer is the genuine Parker fixed hammer impact crusher for the production of high quality, high strength cubical shaped aggregates in secondary or tertiary, low abrasion applications. No shear or compressive crushing action takes place and every stone is broken by impact forces at its weakest point to provide an exceptionally strong ...

Онлайн консультация